Energy System Basics

Electrical System

Overview

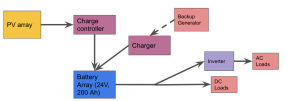

The electrical system for the station is a solar electrical system, designed to work off grid.

Our system comprises of 5 major components: Solar panels, a charge controller, batteries, an inverter, and a charger. These components work together to provide electrical power to the station. In the section below, we'll describe what each of these components does.

Major Components

The solar panels (also called a photovoltaic, or PV, array) convert sunlight into electrical power. This electric power is direct current. The exact voltage and current provided by the panels depends on the type and make of the panels and the current weather conditions. In our system each panel has a maximum power output of 360 W.

The charge controller takes the output electricity from the solar panels and converts it to the correct voltage required to charge the batteries.

The batteries store the electrical power from the PV array, so that the station can still have electrical power even in weather conditions where the PV array isn't generating electrical power. The batteries for our system are AGM batteries, a type of sealed lead-acid battery. Our system contains 2 batteries, each one 12 V, 200 Ah, wired in series, such that the total array is 24 V, 200 Ah. A battery monitor keeps track of the charge of the battery array.

An inverter takes the direct current output from the batteries, in our case at 24 V DC, and transforms that to 120 V AC, which is the same as a typical household outlet in the USA.

In cases of consistently bad weather or higher than expected energy use, the batteries may run low. In this case a charger can be used with external 120 V AC (either from a backup generator or from nearby utility, if available) in order to charge the batteries.

Sizing

In order to size the components for our system, we first had to determine our expected daily load. In order to do that, we had discussions with the researchers at the SCG (our end users) about their expected uses for the house. A table of the maximum expected daily load is listed below:

| Energy Drains | Item | Energy Consumption [Watts] | Duration of Energy Consumption (daily), [hours] | Watt-hour/day | Percent of Daily Energy Consumption |

|

Necessary

|

Interior Lighting | 80 | 5 | 400 | 25.64% |

| Energy Monitoring System | 1.5 | 24 | 36 | 2.31% | |

| Ventilation System | 23 | 8 | 184 | 11.79% | |

| Outlets (computer) | 180 | 5 | 900 | 57.69% | |

| Microscopes | 20 | 2 | 40 | 2.56% | |

| TOTALS | 1560 |

Using this information, we then sized the solar panels and batteries. Our solar panels were sized such that they could provide, assuming 4 hours of sunlight at the panel's nominal output, at least 1.5x the maximum anticipated daily load. This meant that our PV array had to have a nominal rating of at least ~600 W. After looking at different available panels, we chose to purchase two LG Neon2 panels, each rated at 360 W, for a total nominal rating of 720 W.

Next, we sized the batteries such that their stored capacity was at least 1.5x the maximum anticipated daily load (~2.3 kWh). Our main options for battery types were: flooded lead-acid, sealed lead-acid, and lithium polymer. We ruled out flooded lead-acid, as those require frequent maintenance, and we also ruled out lithium polymer, as those can freeze in cold conditions, as the station will not be heated at all times during the winter.

As a result, we chose to use two 12 V, 200 Ah AGM (sealed lead-acid) batteries. With sealed lead-acid batteries, only 50% of the battery capacity is usable, as discharging the batteries below 50% can significantly reduce the lifetime of the batteries. This means that our battery array has an approximate usable capacity of around 2.4 kWh.

Heating and Cooling

Station heating will be provided by small electric heaters, which can be used as needed. Cooling, during the summer, can be provided by opening windows.

For heating and cooling, we initially explored some alternative options, such as a heat pump (for both heating and cooling), or a wood stove for heating. We found the heat pump to be impractical, as the electrical demand of one was too high (typical power input of the smallest heat pumps is still around 800 W).

We eventually decided against the wood stove, as it, and the required clear space around it, take up significant floor space. Considering that, and that the highest period of use for the station will be the summer, we decided against the wood stove.